Production Visits - Bit Stool

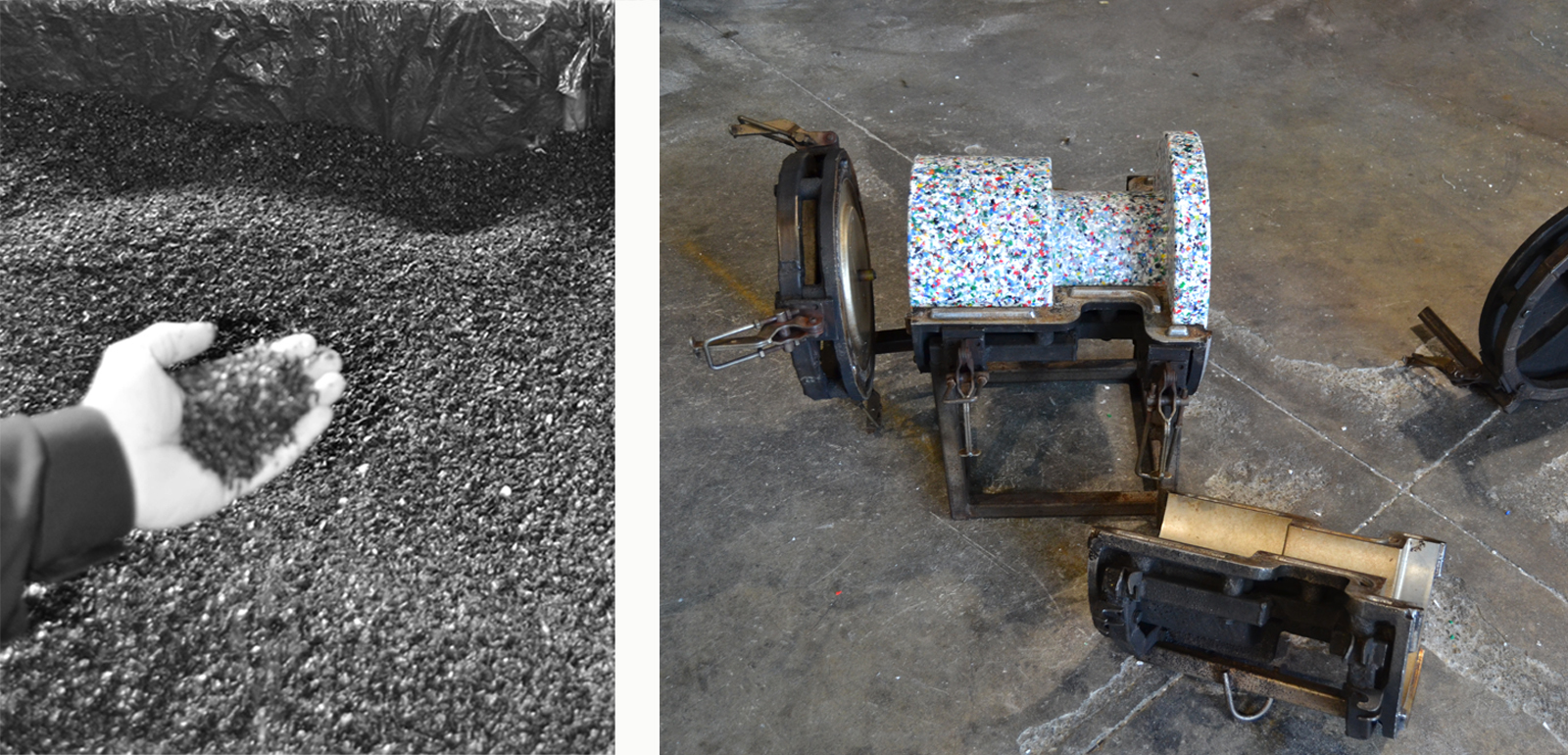

Explore the production process of the Bit Stool, a multifunctional design that is a bit more resourceful in its production. Bit Stools are crafted using recycled plastic. The plastic originates primarily from post-industrial waste, mixed with smaller portions of household waste.

Precision in the Manufacturing Process

Once the plastic waste is collected, it is chopped into smaller fragments and color-sorted into the 10 different Bit Stool color variants. For the forming of the Bit Stool, the color-sorted plastic fragments are weighed to ensure that the exact amount required is used: 4.5 kg. The material is poured into the Bit Stool molds, and cast using a rotational molding technique with a temperature of precisely 120°C.

This is particularly important, since overheating can damage the structure of the plastic, making it unsuitable for further recycling. Instead, the 120°C melting point enables the Bit Stool to be reheated and recycled repeatedly without altering the material’s properties.

Designed for Versatility

The result is a circular design suitable for a wealth of functions and settings. Bit Stool can be used in indoor and outdoor environments, withstanding temperatures from -10°C to +50°C. Its straightforward design makes it ideal for numerous uses, from additional seating to a pedestal for a vase or a side table.

A Focus on reusability

Bit Stool’s design promotes long-term durability and useability. The material used can be reheated and reused, maintaining the integrity of the plastic and making the stool a product with a circular life cycle.

Bit Stool is available in three different shapes and 10 different colors.

Discover all Bit Stools below.